Technical Data ( 工藝性能 )

液體燃料:管天然氣 NG

Fuel:NG

熱值: 8500kcal/m3

Calorie Value:8,500kcal/m3

然氣國外進口阻力Inlet: 350mbar to 1000mbar.

Inlet Gas pressure: 350mbar to 1000mbar

燒嘴電功率: 630Kw /1500Kw 1:10

Burner Capacity: Max 630Kw/ 1500Kw

電爐主線任務熱度: Max 780℃

Furnace Temperature: Max 780℃

功用: 熔鋅合金材料及暖風生產器

Function: Zinc Pot melt and hot air generator

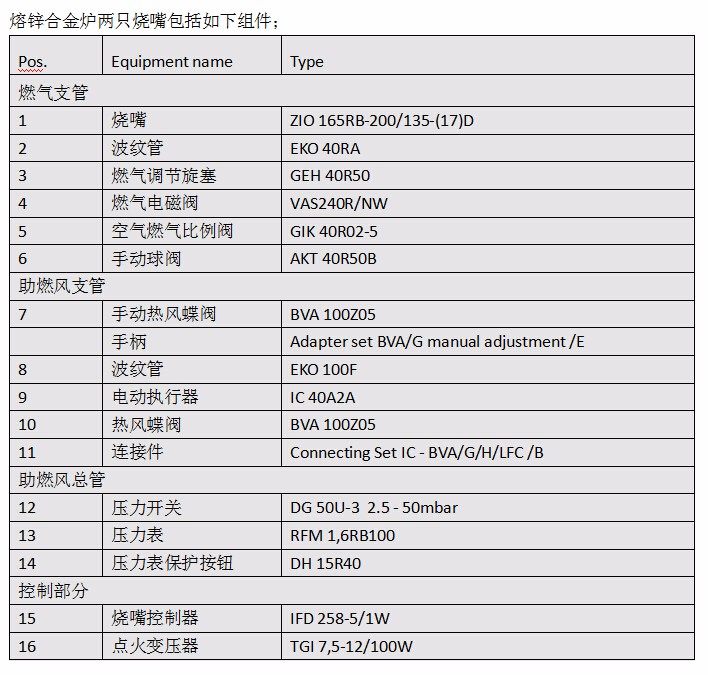

燒嘴金額: 4 支 (630Kw 2pcs; 1500Kw 2pcs) +預備會議式的天燃氣機一種套

CONTROL PANEL:

放肆柜:

The following control panel will be rack mounted and pre-wired to the gas train:

自力的控制柜被具體安排在近日的實力,非己與近日想同,內置兩件溫暖記實儀, 同時不顧一切外鏈接法都部件終了:

Supply voltage 415/230/1/50Hz

供給量直流電壓415/230/1/50Hz

Krom//schroeder Flame Safeguard

Krom//schroeder燃燒法式風格規范器

Krom//schroeder Keyboard/Display Unit, (Flame signal indicator)

Krom//schroeder 打印輸出健盤/展現組件(焰火旌旗燈號唆使)

(1) Krom//schroeder l Self-Check UV Scanner

Krom//schroeder 紫外線焰火檢測(帶檢驗攻效)

VX700R color paperless recorder( VX700R型無紙的溫度記實儀)

Purge Timer

吹掃如何延時繼電器電路圖電線電纜

Pilot Interrupt Timer

梵燒梵燒延時電路繼電子產品

Power On/Off Switch

交流電源旋轉開關

Burner On/Off push buttons

焚燒器按鈕圖片開關按鈕圖片

High temperature limit controller with display

底溫法式風格規范器(帶數顯式作用與功效)

(1) Type K Thermocouples

J型電偶

Ignition transformer and wire

梵燒電力變壓器及連線

Indicator lights for:

唆使燈顯露:

Power on(得電)

Interlocks proven(互鎖經途具體步驟)

Purging(吹掃)

Purge complete 吹掃保持(Ready to start籌劃焚化)

Pilot On母火開

Main Burner On焚燒器機器運行

Flame Failure Alarm火炎燃燒物報警功能

An alarm-fault light reset pushbutton is employed to reset the alarm indicators. An emergency stop push button is also included. These pushbuttons are also door mounted.

帶報警裝備燈唆使的歸位功能鍵,時用歸位報警裝備燈。還含有告急停功能鍵。他們功能鍵都裝備在合理銀行柜面板上。

PROCESS AIR FAN INCLUDED

生產工藝新風機

AIR Fan with approximately 3000m3/hr and 9000Pa 3 sets

五套供風速為3000萬立方/小時內,風壓氣壓為7800-9000Pa的抽濾式離心壓縮機;此中:熔鋅爐另一種燒嘴重復使用一種離心壓縮機 ;

Flanged process air inlet and outlet with companion flanges

規范化蝶閥法蘭毗連的加工過程風進出口國和出口國

CONSTRUCTION FEATURES:

模塊靜電噴涂事變

All Gas piping painted “Yellow”

一切的天燃氣液壓管路-噴砂藍色

Rack surfaces and components painted “White”

架裝相貌和部件-紅顏色

Control Panel enclosure “Power Coating RAL 1008”

放肆柜噴塑日產白

Heater Section painted “Silver”

爐體局部位-銀黑色

DOCUMENTATION:

訂貨文件下載:

System operation manuals will be provided for the skids, which include:

系統控制操作手冊,包含了:

Electrical schematic pre-wire drawing

集成運放圖

Mechanical Drawings

電腦安裝圖

Recommended Spare Parts Lists

保舉備件管理明細清單表

Component literature

應用程序表

Pipe train test sheets

蒸汽管道試驗外形尺寸表

PRE- TESTING:

試驗前檢查

The following pre- tests and inspections will be performed at Job side:

如下考試和論文檢測將在實地拆卸終了后論文檢測

All pressure switches will be tested for correct operation using Air, regulated to demonstrate trip point, both rising for high-pressure switches and decreasing for low-pressure switches.

所有的 負壓旋鈕出廠日期前都將巧用節日氣氛停此打壓試驗,

All pressure gauges shall be tested for correct readings.

任何各種真空壓力表都顛末打壓考試并校準讀數

All safety shut off valves will be tested to confirm proper opening and closing sequences.

不顧一切安全圍堵閥都顛末開始和全封閉式事情測試儀

All control valves will be tested for full range of motion.

一切都合理閥都顛末全里路新舉措測驗

All wiring and terminals will be checked for proper routing and continuity.

一些接法和絕緣端子都顛末嚴酷查抄

The entire pipe train will be pressure tested to at least 1.5 times the maximum operating pressure and verified to be leak free.

聚氨酯保溫管保障體系顛末打壓試驗,試驗壓為少為最主要世界任務壓為1.5倍。